Innovation and new product development

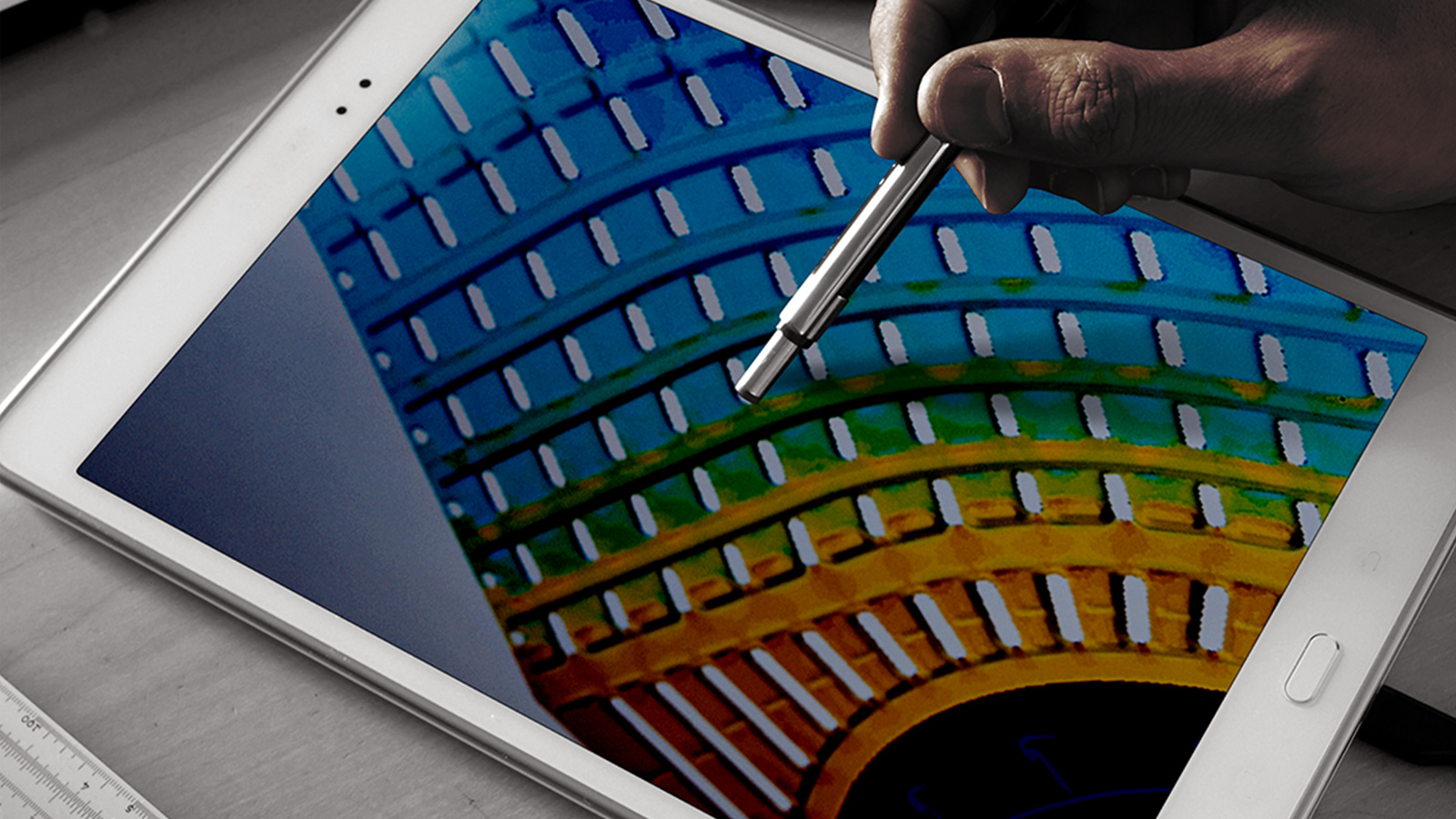

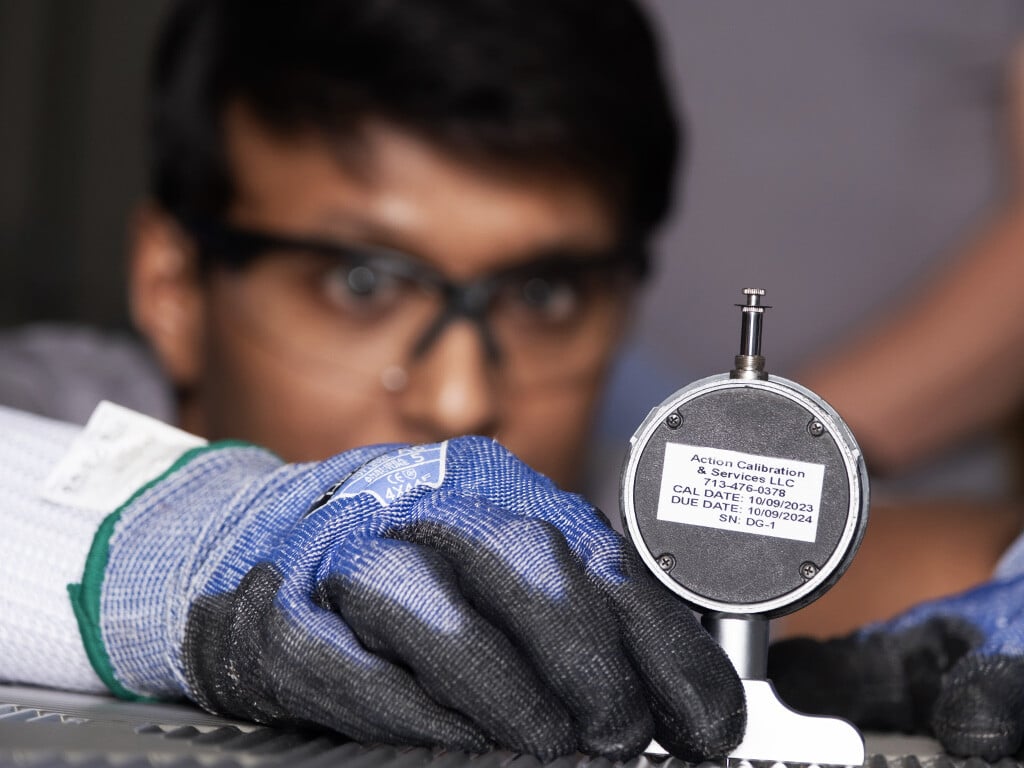

Driven by innovation, our Research and Development department focuses on developing groundbreaking products and improving existing ones to meet market demands and technological advancements. Our team closely examines patents to create unique solutions, particularly in advancing materials science for heat exchanger "ceiling technology". We explore new materials and coatings to enhance performance, reduce fouling, and prolong product life.

AT Tranter

We focus on solutions that makes a difference

- Thermal hydraulic performance: Focusing on optimizing thermal efficiency and flow dynamics to maximize heat transfer while minimizing energy consumption.

- Pressure rating enhancements: Engineering solutions that withstand higher pressure demands, suitable for critical applications in industries like oil and gas and marine engineering.

- Design innovation: Introducing groundbreaking designs that enhance performance and ease of maintenance, including the development of new heat exchanger plates and the application of 3D printing for rapid prototyping.

- Sustainable solutions: Developing designs that reduce environmental impact and operational costs, aligning with global sustainability goals.

- Advanced materials: Utilizing cutting-edge material science to improve the durability and performance efficiency of our heat exchangers.

Resource center

Discover our latest videos

Energy, Process industries Marine and shipbuilding Sustainability

Plate series introduction: The GT-165

Resource center

Explore our latest articles

How advanced thermal hydraulics solve your process efficiency challenges

Sick of not getting quality parts in time? Tap into our global supply chain and end the hassle

Why an OEM service partner for heat exchangers beats a non-OEM on any given day

Top 7 benefits of gasketed plate heat exchangers in industrial processes

Our heat exchangers

Heat exchangers for your every need

Resource center

Download our latest guides and literature

Energy, heating and cooling Sustainability

Tranter heat exchangers in the sustainable data centers

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Heat exchangers for post combustion carbon capture applications

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Are you considering obtaining heat exchangers?

Contact us for more information!